top of page

Make Your 3D Dreams a Reality

Precision, speed, and quality: Our 3D printing services deliver it all

1000+ Happy customers

Customized Products

Versatility

Global Presence

Why Choose

3 Zero?

Explore the best design service

Durable, High Quality Materials

Step into a new dimension to experience the power of depth and unleash your imagination.

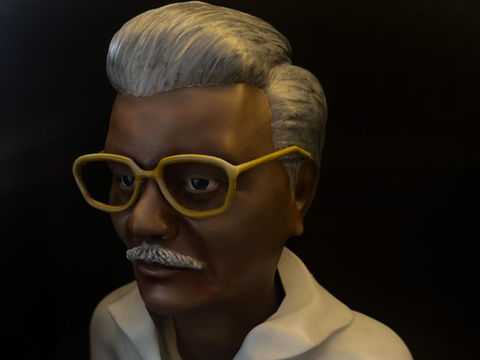

Best Finish and Paint Quality

Experience the pinnacle of quality and precision with our painting services.Unleash your creativity with our high-quality painting options and finishes.

When durability matters, choose our high-quality materials.

Refining Perfection

Transforming Raw Designs,Adding the Finishing Touches,Enhancing Realism to Perfecting the Vision.

Testimonials

Our Clients

FAQ

FAQ

General

bottom of page